Why you need Failure Modes Effects Analysis

Failure Modes Effects Analysis (FMEA) is used during the development of new products and processes to identify, control and eliminate the causes of failure, while mitigating the effects of faults or error conditions that may arise.

This is achieved by introducing controls including:-

- Prevention Controls to eliminate or reduce the causes of failure, and

- Detection Controls to give warning of a fault or error condition

Or

- Changing the design to eliminate the failure mode or mitigate the effects of failure

- Changing the production process to prevent errors occurring

FMEA Method

Failure Modes Effects Analysis is normally undertaken by a team of people with knowledge and experience of the product or process under consideration.

The level of risk associated with particular failure modes is determined by considering:-

- The effects the failure will have when it occurs (Severity), and

- The chance that the causes of failure will be present (Occurrence), and

- The ability to detect when the error condition is present (Detection) allowing the effects of failure to be prevented or minimized.

If the current situation is considered unacceptable action must be taken to improve the product design or manufacturing process, to control the causes failure and limit their effects, or alert people to the need for timely intervention when the causes of failure are present.

FMEA is therefore an essential part of the risk management strategy, protecting you, your customers and end users from mistakes in the specification, design, production or operation of the equipment and components you supply, purchase and use.

For more information about Stunell Technology’s training and support for Failure Modes Effects Analysis, why not contact Phil Stunell now?

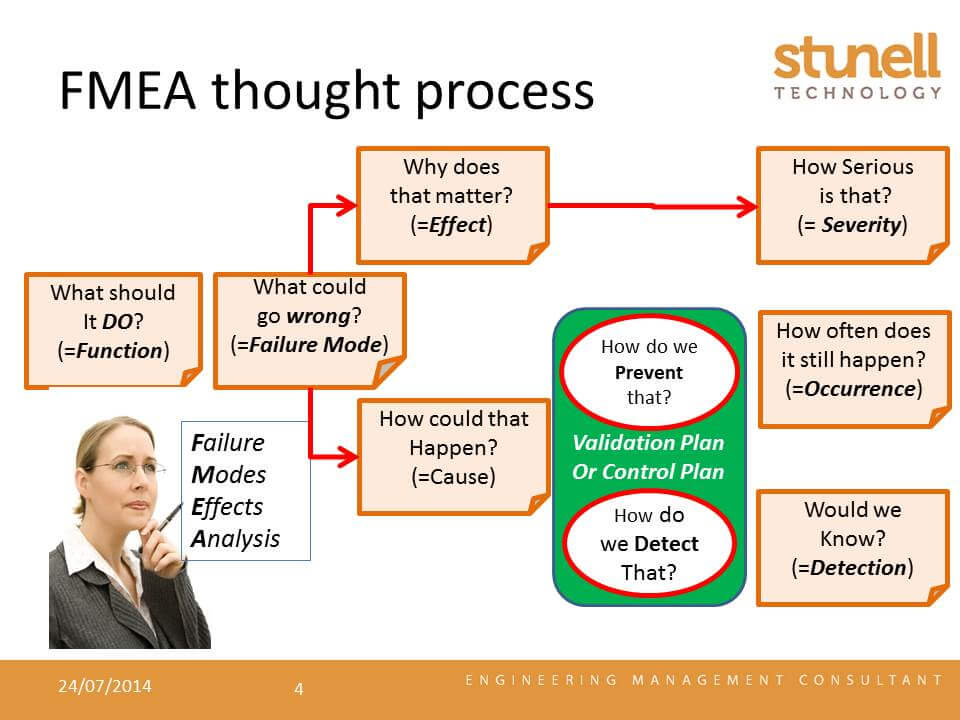

FMEA Process Flow Diagram

Principles of Failure Modes Effects Analysis

The FMEA process records and documents what is currently known about:-

- How the product or process may fail to meet the customer’s expectations (The failure modes),

- The consequences of failure, within the extended supply chain or in use. (The effects of failure)

- The potential causes of failure, including errors and omissions in the specification, design or production process that could generate, or allow, the failure to occur

- The controls or countermeasures introduced to prevent failure, by eliminating the causes, or to detect the error condition and alert you to potential failure so that the effects can be mitigated or avoided.

Any action that is identified in the FMEA to reduce and eliminate the causes of failure or alert you to the failure condition is a CONTROL in FMEA terminology. Implementing appropriate controls identified in the FMEA will improve product quality, reduce or eliminate failures and prevent loss or injury caused by product defects.

Types of FMEA

Product failures maybe caused by errors or omissions (mistakes) in the way the product or process has been:-

- Specified,

- Designed,

- Processed during production, or

- Maintained and Used

Anything that ‘prevents’ or ‘detects’ a failure mode, fault condition or non-conformance is described as a control in the FMEA, but these are often documented in different ways, as shown in the examples below:-

| Document | Prevention Control | Detection Control |

| Specification | Compliance with ‘in-house’ or public standards.Use of ‘fail-safe’ and ‘proven’ design features.

Use of ‘capable production processes’ and ‘known suppliers’ |

Warning systems and displays that alert usersto a ‘fault’Scheduled inspections |

| Design Validation Plan | Application of design standards and design codes.Design calculations and simulations.

Selection of suppliers with proven process capability. |

Prototype testing and validation to in-house and public standards.Design reviews and audits against established standards

Homologation and Type Approval Testing |

| Process Control Plan | Use of calibrated tools and equipmentStatistical Control (SPC) of process parameters

Operator training |

Inspection and gauging of parts producedStatistical Control (SPC) applied to product characteristics |

| Maintenance Plan | Scheduled replacement of filters and ‘wearing components’Equipment Calibration | Condition monitoring systems and scheduled inspections

Warning systems that alert operators to equipment failures |

Examples of Controls

These controls contribute to the risk management strategy, minimising the risk of failure and potential product liability claims.

The FMEA process can be simplified if we align the FMEA with the ‘control documents’ shown above, and use separate FMEAs to identify the possible failure modes and appropriate controls in each of these documents, often developed at different stages in the project.

Adopting this approach allows the use of different FMEAs as described on the right:-

FMEAs Aligned to Control Documents

Each of the FMEAs is compiled using a similar process, with content that reflects the purpose of the FMEA and the type of controls that can used to reduce or eliminate the identified failure modes at that stage of development.

| FMEA | Used to Develop.. | That Describes |

| System (SFMEA) | Product Specification | Essential product features and the design requirements for components and sub-systems. |

| Design (DFMEA) | Design Validation Plan | Methods used to gain confidence in the design including the requirements for product testing, analysis and simulation |

| Process (PFMEA) | Production Control Plan | The controls required to maintain ‘process capability’ and detect non-conforming product. |

| Machinery (MFMEA) | Maintenance Plan | The actions and controls required to ensure that production plant and equipment performs to an acceptable standard. |

Potential Failure Modes

A failure mode describes how (not why) a product or process may fail to satisfy a known requirement or the customer’s expectations. When the requirements have been clearly defined or agreed, describing possible failure modes becomes relatively simple, for example:-

| Requirement or Expectation | Potential failure mode |

| Radiator contains water at 5 bar, 120 degrees C | Radiator does not contain water, when hot (water leaks from top tank) |

| Door does not trap fingers | Fingers trapped in door |

| Bolts tightened to specified torque | Inadequate torque applied to bolt |

Examples of Potential Failure Modes

Because the potential failure modes are related to the functional requirements or customer expectations of the product or process, it is essential that these are well defined during the FMEA process. Whenever possible the ‘requirements’ should also be quantified with specific targets, rather than being vague statements of intent.

Effects of Failure

The effects of failure documented in the FMEA assume that the potential failure mode will occur and describe the direct and predictable effect of the failure on the production process, or the users experience of the product. It is good practice to describe the effects of failure as they would be experienced at the next stage of the production process or point of discovery, or by the user, without indulging in wild speculation.

However, if an error or omission in production could pass through the system undetected and reach the customer you must consider the impact the non-conforming part may have on the user’s experience.

Causes of Failure

Although every failure mode will have at least one possible ’cause of failure’, many will have several ‘potential causes’ that must be recognised and controlled if failure is to be avoided.

The ’causes of failure’ describe the specific errors and omissions in the design or production process that could generate or allow the failure mode being considered. If all the causes of failure can be identified and eliminated, then the failure mode will also be eliminated.

FMEA Controls

The risk of failure can only be reduced by implementing controls that:-

- Prevent or eliminate the causes of failure, or

- Detect an ‘Error or Fault condition’ and allow corrective action to be taken to prevent or mitigate the consequences of that error condition or fault

Effective risk reduction strategies normally rely on a combination of Prevention Controls, to reduce the ‘occurrence’ of failure causes and Detection Controls that warn of an ‘error or fault condition’ associated with particular failure modes.

However, detection controls are only effective if they enable somebody to take action to avoid the failure, or at least contain the problem. The use of detection controls implies that there is a planned response to the warnings given (a reaction plan) and that people will have sufficient knowledge, skill and opportunity to take ‘appropriate action’ that will prevent or mitigate the effects of failure.

FMEA Training

Stunell Technology delivers ‘in-house’ training courses for FMEA team members and leaders, for groups of up to 16 delegates, for information please contact us