During the 1980’s the automotive industry in Europe and the USA became increasingly concerned about competition from Japan and Asia, because new entrants to the market were gaining significant market share and attacking their traditional domination of the global automotive market. In order to understand the source of their apparent competitive advantage, and the threat to their market dominance, the industry sponsored a research project run by Massachusetts Institute of Technology (MIT), to compare and contrast different companies in the industry. (more…)

GM’s Ignition Switch Recall: FMEA Analysis

General Motors (GM) has launched a series of product recalls since January 2014, due to problems with ignition switches installed in vehicles built since 2003 – which may result in ‘moving stalls’ or disable the air bag system moments before a crash. GM acknowledges that at least 13 people have been killed in crashes when the air-bags did not deploy – although air-bag deployment would have been expected, judging by the vehicle damage and circumstances of the crash.

General Motors (GM) has launched a series of product recalls since January 2014, due to problems with ignition switches installed in vehicles built since 2003 – which may result in ‘moving stalls’ or disable the air bag system moments before a crash. GM acknowledges that at least 13 people have been killed in crashes when the air-bags did not deploy – although air-bag deployment would have been expected, judging by the vehicle damage and circumstances of the crash.

The problems, caused by poor design design of the ignition switch, were first reported to GM during the launch of the Chevrolet Cobalt in 2003, by employees driving early production vehicles in their ‘Captive Fleet Trials’ program, as well as journalists during the press launch, who reported ‘moving stalls’ – when the engine shut-down as the ignition key moved out of the “run position” while they were driving. (more…)

GM’s Ignition Switch Recall: The story so far…

General Motors (GM) has become embroiled in a political and legal firestorm, following it’s acknowledgement that from 2003 until 2007 it supplied Cobalt and Ion cars fitted with a dangerous and defective ignition switch, that could prevent the air bags deploying in an accident – resulting in at least 13 unnecessary deaths since 2003.

Anton Valukas, a lawyer commissioned by GM to investigate ‘how and why we got into this mess’ has now produced his report for the GM Board – and a redacted copy is available on the NHTSA website as a free download. Based on detailed research and over 300 witness interviews, the 325 page report presents a remarkably frank and brutal account of the events that allowed a life threatening defect to reach production – and GM’s failure to identify or solve the problem for over 10 years.

Like most ignition switches, the unit fitted to the GM Cobalt and Ion cars had 4 distinct positions – controlling the power supply to the vehicle’s electrical systems.

| Key Position | Active Electrical Systems |

| Off | Vehicle Lights, |

| Accessory | Vehicle lights, In car Entertainment etc. |

| Run | Vehicle lights, In car entertainment Engine and drive line, safety systems |

| Crank / Start | Vehicle lights, In car entertainment Engine and drive line, safety systems, Engine Start. |

The problem started with poor design and specification of the ignition switch, that required minimal effort to rotate the key in the lock barrel. This allowed the key to turn from ‘Run’ to ‘Accessory’ or ‘Off’ when it was knocked by the driver’s knee or subjected to severe vibration. Unintended movement of the key could occur during normal driving, causing a ‘moving stall’ – or as the vehicle crossed rough ground during a pre-crash event – preventing air bag deployment on impact. (more…)

Product Recalls – and How to Prevent Them

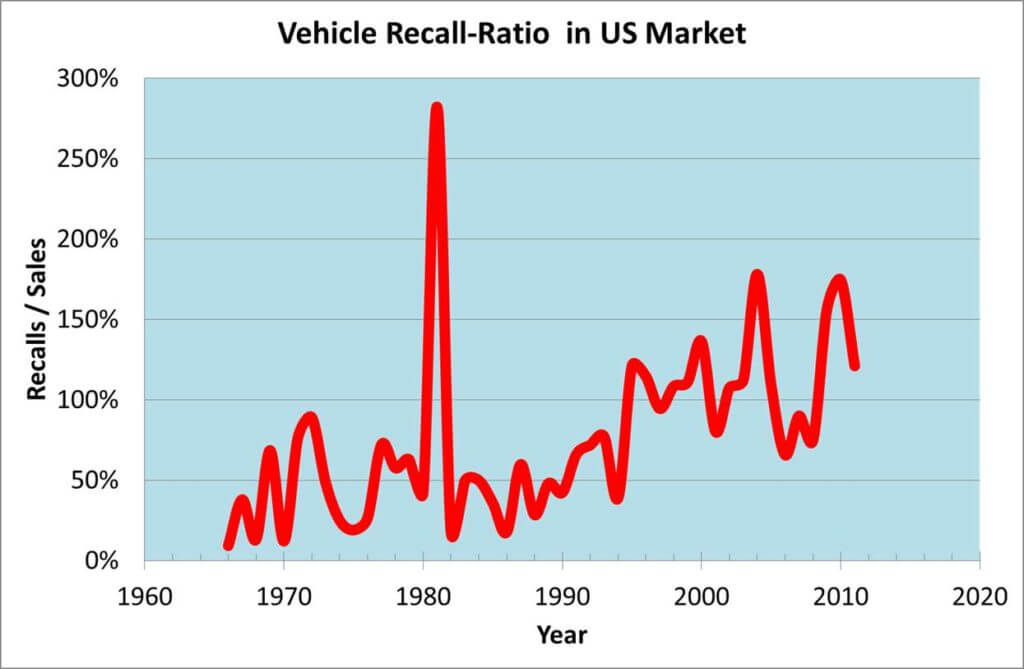

Vehicle manufacturers and component suppliers are becoming uncomfortably familiar with the need to recall their products to fix ‘safety defects’ – and the negative publicity that such recalls can attract. In fact, data supplied by NHTSA – the US regulator for vehicle safety – shows that a ‘typical vehicle’ sold in the US will need to be recalled more than once to correct safety defects – and the situation has been getting progressively worse since the 1990’s. (more…)

Vehicle manufacturers and component suppliers are becoming uncomfortably familiar with the need to recall their products to fix ‘safety defects’ – and the negative publicity that such recalls can attract. In fact, data supplied by NHTSA – the US regulator for vehicle safety – shows that a ‘typical vehicle’ sold in the US will need to be recalled more than once to correct safety defects – and the situation has been getting progressively worse since the 1990’s. (more…)

FMEA for Children

The purpose of a Failure Modes Effects Analysis (FMEA) is to identify how a product or process could fail to satisfy customer requirements and expectations, ensuring that action is taken to mitigate the effects of failure so that the impact on users is reduced to an acceptable

level.

We recently identified a quality problem with the Fisher Price Musical Gym. Like many toys this requires a couple of AA batteries to power the audio output – but fitting them proved difficult due to a manufacturing defect shown below: (more…)

Stunell Technology appointed as a Qualitin Business Partner

Although Key Performance Indicators (KPI’s) are commonly used to measure the performance of organisations, departments or processes – and we now have access to more historic data than ever before, historic performance data will not drive process improvement without an effective management system.

Working with Gerdau the Brazilian steel producer, Qualitin have developed a new new approach to KPI Management that uses historic performance data to drive continuous improvement, which has been tried and tested by many of the most successful companies in Brazil.

As Qualitin expands from Brazil to support their global clients, they are appointing Business Partners in the strategically important UK and European markets, to support the implementation of their ICG tool kit for KPI Management. (more…)